Our services

What We Provide

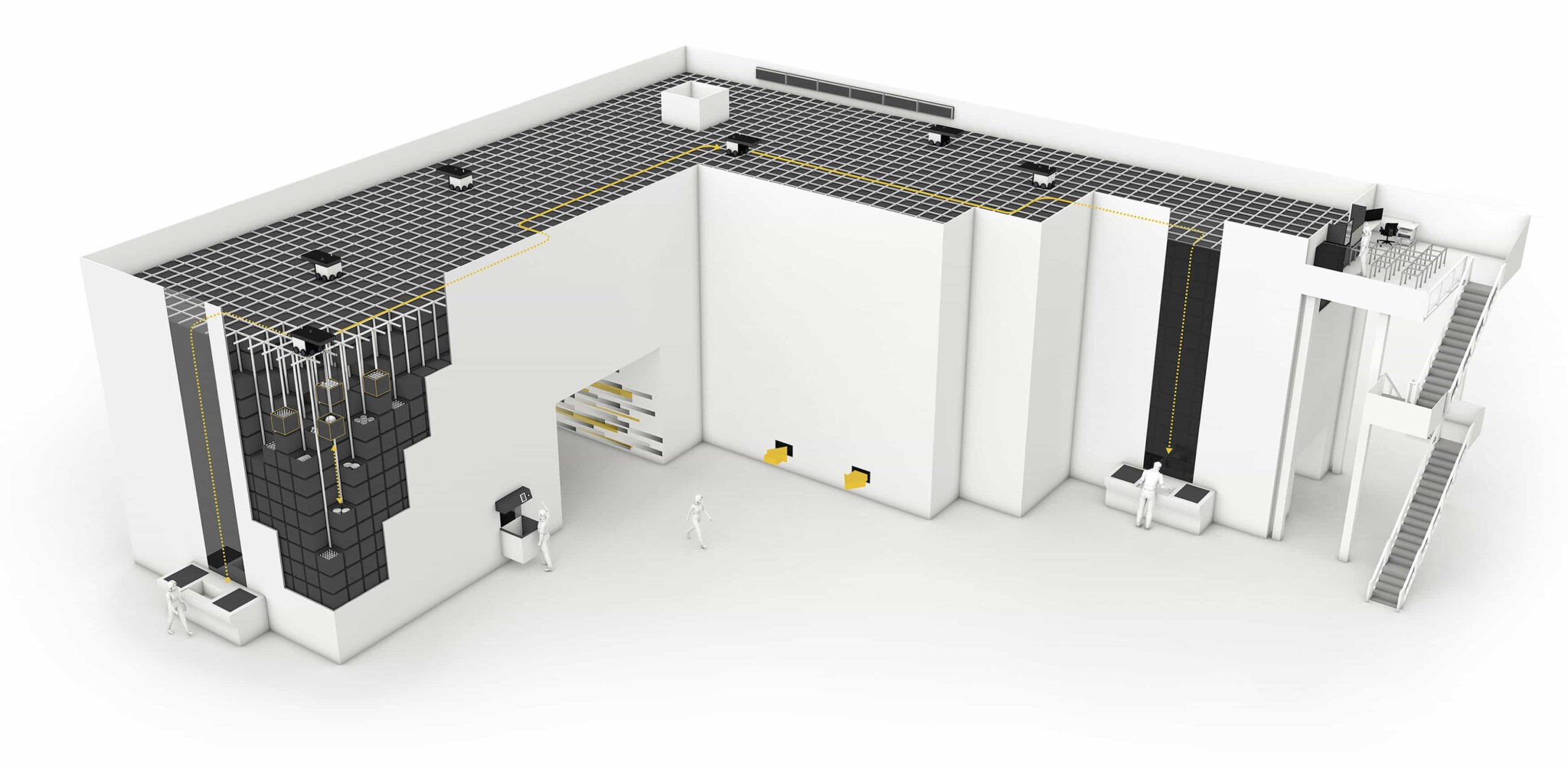

Leverage the advancements of Automated Storage and Retrieval Systems (ASRS) for enhanced operations and space optimization.

Explore next-gen warehouse efficiency through Automated Storage and Retrieval Systems (ASRS), optimizing operations and space.

We handle the strategizing, planning, and assessing, freeing you to hone your craft. Reach out for futuristic warehouse solutions

Specialized consultancy in warehouse operations: Automated Storage and Retrieval Systems, Conveying Systems, Palletizing, and Automated Guided Vehicles.

Every penny counts. Our holistic approach targets not only system improvements but also the underlying costs associated with warehouse operations.

Stagnation is the enemy of progress. We take a deep dive into your current operations, pinpointing areas that need enhancement.

Space is a premium asset. We specialize in maximizing the utility of every square inch of your facility. Through high-density storage solutions and efficient layout designs, we help reduce your warehouse’s footprint.

Leverage the advancements of Automated Storage and Retrieval Systems (ASRS) for enhanced operations and space optimization.

Your partner should offer solutions that grow with you. Assess their capacity to handle increased demands and their readiness to adapt to changing business scalability needs.

After-sales service and continuous support are key. Ensure your partner is responsive, knowledgeable, and can offer timely assistance when you face challenges.

Modern warehousing demands the best in tech. Your ideal partner should be abreast of the latest advancements and offer systems that seamlessly integrate with your existing infrastructure.

Operational safety and compliance is non-negotiable. Your partner should prioritize safety protocols and remain up-to-date with industry regulations and standards.

In the competitive…

In today’s competitive…

We're eager to answer your initial queries right here. Happy learning!

ASRS is a computer-controlled system for efficiently storing and retrieving goods in a warehouse or distribution center.

ASRS minimizes manual handling, reduces errors, and optimizes space by utilizing high-density storage, leading to faster, more accurate order fulfillment.

Manufacturing, e-commerce, retail, and any business with high-volume storage and retrieval needs can greatly benefit from implementing ASRS.

Most ASRS solutions are designed to seamlessly integrate with a variety of WMS platforms, ensuring smooth operations and data flow.

While the initial investment can be significant, the long-term savings in labor, reduced errors, and increased storage capacity often lead to a favorable return on investment.

ASRS systems are designed with safety in mind, reducing the need for manual lifting and transportation, which can lead to accidents. Additionally, they often include safety features like alarms, emergency stops, and protective barriers.

Yes, many systems can be customized with specialized grippers or attachments to handle a wide range of product shapes, sizes, and fragilities.

Implementation timelines vary based on system complexity, customization needs, and facility size. Typically, it can range from a few months to over a year.

While ASRS systems are designed to be user-friendly, training is essential to ensure safe and efficient operations. Most suppliers offer comprehensive training as part of the implementation.

Most ASRS providers offer robust support and maintenance services to address any issues. It's crucial to have a regular maintenance schedule and ensure system backups for minimal disruptions.